I spent much of senior year leading a redesign of Robot Soccer Team’s electronics for increased reliability, flexibility, and backwards communication. The robots have two way communication with a central computer over Xbee Radios, 3-phase brushless motor controllers that pull up to 5 Amps of current each, and capacitor charger that lets us driver a solenoid with 250 Volts to kick the ball at 8 m/s. I also learned about manufacturability when it came time to solder 4000 components to assemble our entire team before the competition.

Fig 1. Reflowing some of the components in a toaster over

Fig 1. Reflowing some of the components in a toaster over

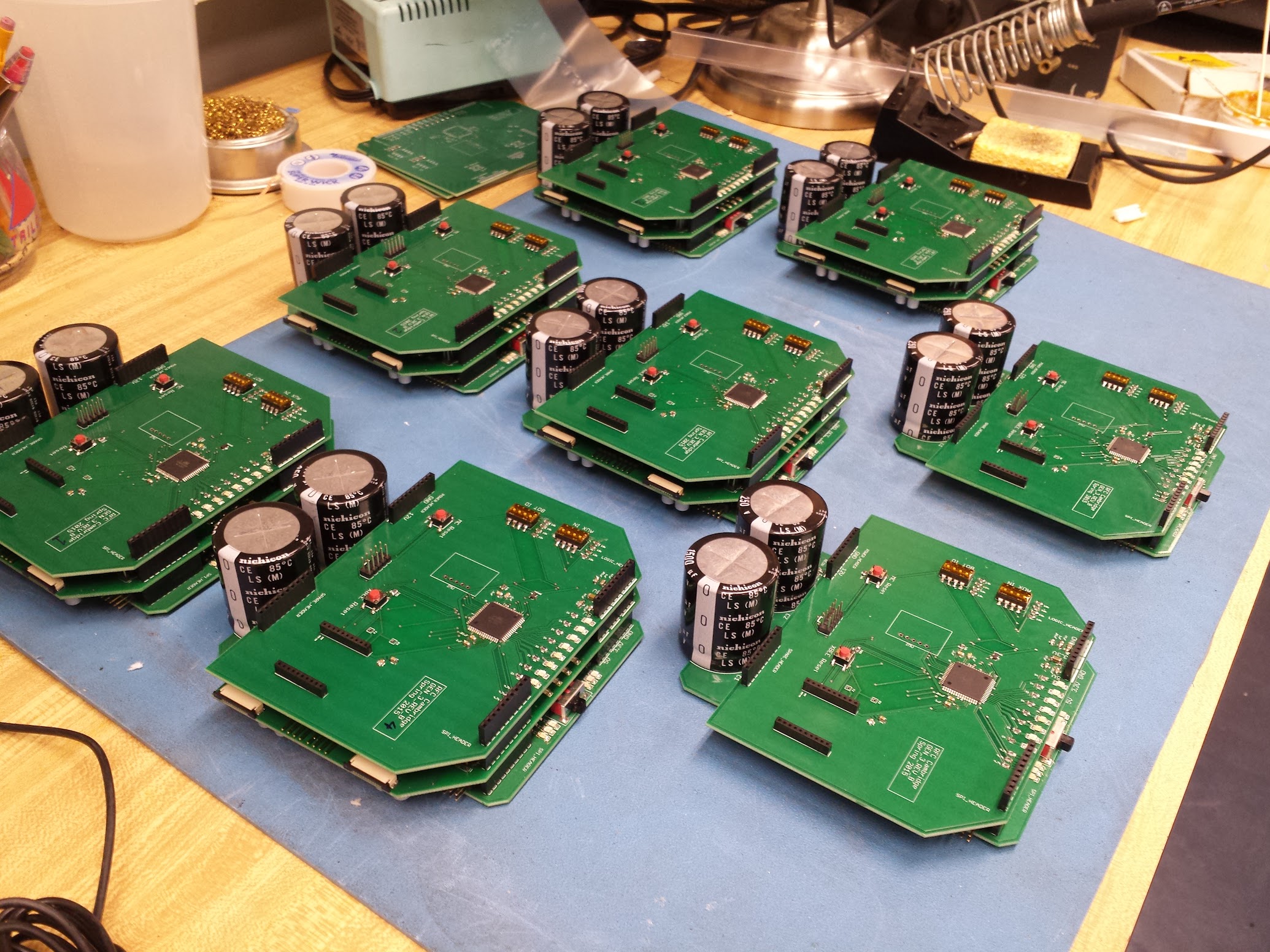

Fig 2. Finished Stacks of PCBs

Fig 2. Finished Stacks of PCBs

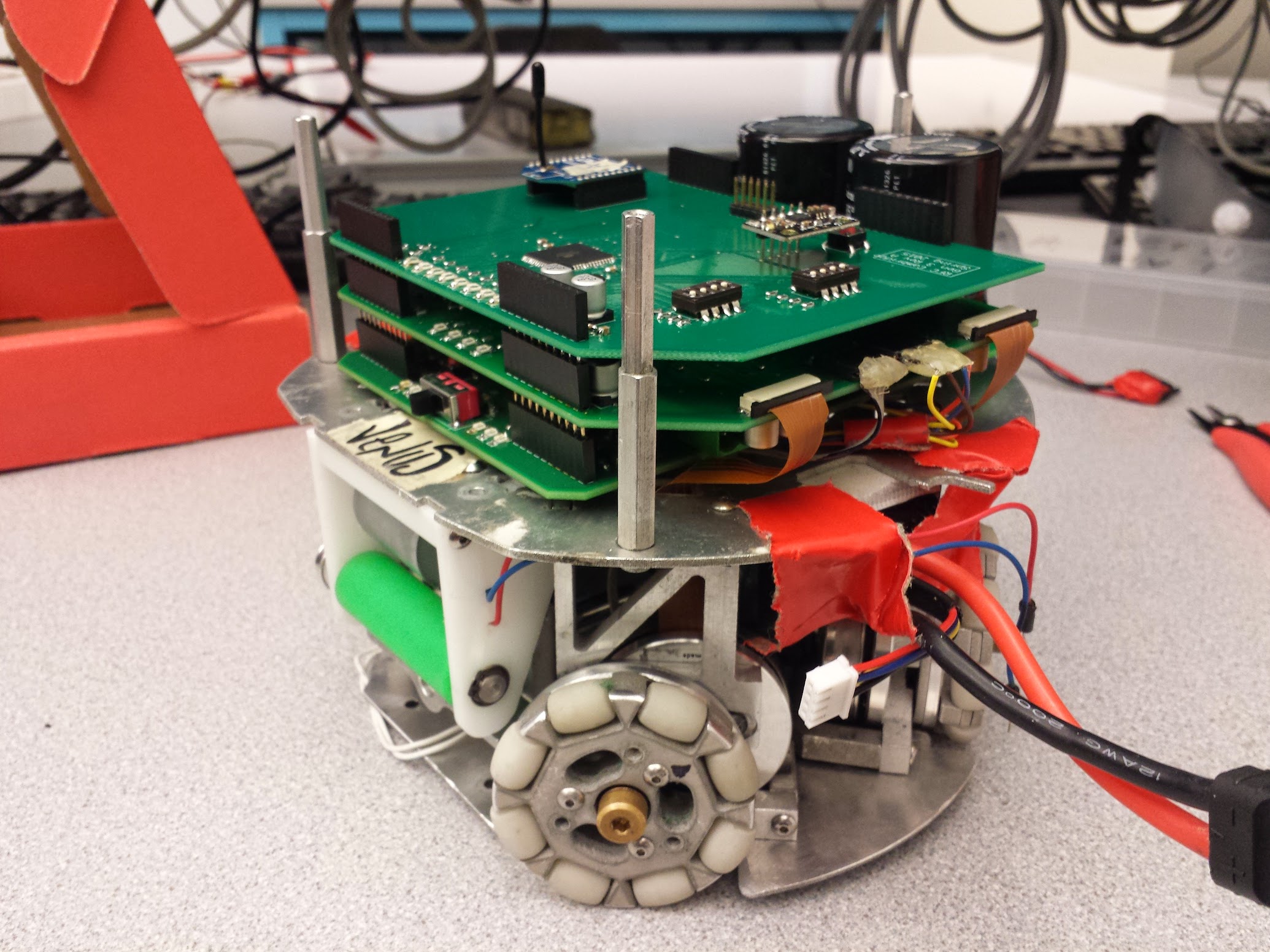

Fig 3. A PCB stack integrated onto a socker robot.

Fig 3. A PCB stack integrated onto a socker robot.